The Nome Schoolhouse in Nome, North Dakota is currently being renovated by two local business owners with a dream. They saw the schoolhouse as the perfect opportunity to combine their businesses, educate others on their business lines and provide a building for the community to use for education, events and socializing.

Who is Behind the Renovation

Chris Ambrust and Teresa Perleberg are North Dakota business owners in a unique industry. Their story is interesting on how together their businesses could build great things.

Chris is the owner, Dakota Fiber Mill, the only full-service fiber processing mill in the Dakotas. Dakota Fiber Mill processes raw fiber (wool, alpaca, bison, goat etc) into yarn and roving. Teresa Perleberg is the owner of Bear Creek Felting. Teresa is a master in the art of needle felting. She has an online academy which offers members access to online tutorial courses instructing how to needle felt various pieces of art. She also raises a large herd of sheep for the wool to use in her kits and supplies which she sells online as well.

Chris has been processing the wool for Teresa for over 10 years. Over that time, they became friends and two years ago collaborated on a wool needle felting cushion. The demand was extremely high and in the spring of 2018 a lightbulb went off for the business partners. Chris had an extra acreage not being used and her mill was busting at the seams. She knew she needed to expand her current building or build new. At that point Teresa’s daughter had just returned from college seeking to become a chef and open a catering business. That is when the lightbulb turned on! The idea was to build a facility that would house not only the mill but guest rooms, classrooms and event space as well as food and beverage. Teresa was on board and Hence Shepard Industries was born.

Renovation Inspiration

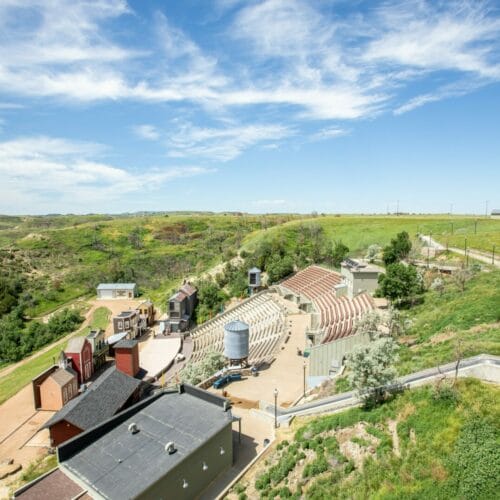

The idea of building new was tossed around but both Chris and Teresa love old buildings which brought them to the idea of renovating one of the forgotten and deteriorating schoolhouses in the area. They “schoolshopped” and fell in love with the Nome Schoolhouse! It was decommissioned fully in 1970, purchased and used mainly for storage. For the past 10 years however, it has been sitting empty.

The business partners prayed for guidance and support. They found out the budget they had originally planned on was much lower than what it was going to take to make their dream a reality. “We became very anxious on the cost, as we were trying to demo all the debris and rotted areas and coordinating engineers ourselves, not having a clue on all the engineering it was going to take before rebuilding started. So many people told us we were crazy and will never be able to finish the project and that we were in way over our heads. All these comments just fueled our fire of determination,” Chris stated.

In the Spring of 2019, the decision to continue or back out had to be made. “We ‘threw out our fleece’, so to say, in the form of a kick starter campaign which is similar to a Go Fund Me campaign but for start-up businesses. You come up with an amount you are going for and if you meet that goal you get the funds, if you don’t meet the goal you do not,” Chris explained. The campaign earned more than they had anticipated. In addition, a successful Nome Alumni helped cosign the loan. The project was moving forward!

Renovation on Phase 1

As they quickly discovered, Chris and Teresa needed help coordinating the renovations. They hired Roers as the Construction Management company for the project. “We have been so pleased with everyone at Roers! It was such a relief to have them take over everything. A big relief as well was how the superintendent on site is handling the actual demo and rebuild. We are saving as much of everything in the school as we can and the crew has been amazing at going out of their way to save wood, doors, molding, etc. We believe they have grown to love the school as much as we do. We couldn’t imagine having a better team onboard with us,” Chris remarked.

Phase one, the gymnasium is now complete. Wood salvaged from an area of the school that had collapsed and needed to be demoed is being used for a bar, shelving and covering support beams. The fire escape steps are being used to access a mezzanine added above the bar, catering kitchen and restroom area which were built.

Phase 2 Making Progress

Phase 2 of the renovation will include the rebuild of the back area of the school. The area will be expanded and include renovations of the existing classrooms and the addition of the guest rooms.

The Roers crew completed  the footings of the addition, with walls to follow. The goal of Phase 2 is for the front of the school to mimic the original front of the building. As you enter the school from the front and walk up the stairs, holding the gorgeous wood railing that so many students have done so before, and step into the main hall, it will look exactly like it did in 1916 with classrooms to the left and right. You will not see the large addition behind the school to the east. “We cannot wait to hear the memories that will flood the minds of those past students,” commented Chris.

the footings of the addition, with walls to follow. The goal of Phase 2 is for the front of the school to mimic the original front of the building. As you enter the school from the front and walk up the stairs, holding the gorgeous wood railing that so many students have done so before, and step into the main hall, it will look exactly like it did in 1916 with classrooms to the left and right. You will not see the large addition behind the school to the east. “We cannot wait to hear the memories that will flood the minds of those past students,” commented Chris.

What the Future Entails

The gym currently houses fiber arts classes as well as the offices for Hence Shepard Industries. Small events are being held and regular open hours for food and beverage to be enjoyed.

The completed schoolhouse will house several entities. The schoolhouse itself is a 501c3 non-profit. Hence Shepard Industries will rent space from the school. The old barn, just steps from the back of the school, will house an education herd of fiber animals. A variety of sheep, alpacas, llamas, camel, goats, rabbits and more will be onsite for groups to be able to view and be educated on where natural fibers come from. Visitors will be able to view the fiber from the goats which create cashmere sweaters. The sweaters can be purchased at Macy’s. The bottom floor of the addition houses the processing mill and packaging area for the products made onsite.

The facilities will offer a variety of classes on fiber arts and crafts, as well as all-inclusive retreats, scrapbooking and wellness events, among others. The event center will be used for conferences, weddings, reunions and so much more. Each of the 13 guest rooms will have a unique décor with private bath. The guests will be treated to amazing food utilizing local produce, farm fresh eggs and grass-fed beef from the Perleberg Ranch, fresh roasted coffee from Valley City and other local delicacies! An onsite retail store will be open daily with tours provided.

The businesses partners have been humbled to have alumni return and tell their memories and stories of their years at the school. The Nome school was influential with teaching students in the past. Now all who visit the renovated school will have the opportunity to learn something new. The future is bright for the Nome Schoolhouse!

Follow the story of this historic building at https://nomeschoolhouse.com/. More construction updates continue to be updated on roers.com.

home of United Way, being at the intersection of our community, was key,” said Kristi Huber, United Way of Cass-Clay President & CEO.

home of United Way, being at the intersection of our community, was key,” said Kristi Huber, United Way of Cass-Clay President & CEO. reaching out to the community and shining a light on homelessness. Here in our local community, each night, more than 1,022 people are homeless. In addition, it is estimated that of the people who are homeless in our community, 23% are children. This

reaching out to the community and shining a light on homelessness. Here in our local community, each night, more than 1,022 people are homeless. In addition, it is estimated that of the people who are homeless in our community, 23% are children. This  JLG Architects and built by Roers, and will efficiently meet the needs of the United Way team, volunteers and community for decades to come.

JLG Architects and built by Roers, and will efficiently meet the needs of the United Way team, volunteers and community for decades to come. We are excited for the work that will be done together – with you – in this new space,” said Huber.

We are excited for the work that will be done together – with you – in this new space,” said Huber.

the footings of the addition, with walls to follow. The goal of Phase 2 is for the front of the school to mimic the original front of the building. As you enter the school from the front and walk up the stairs, holding the gorgeous wood railing that so many students have done so before, and step into the main hall, it will look exactly like it did in 1916 with classrooms to the left and right. You will not see the large addition behind the school to the east. “We cannot wait to hear the memories that will flood the minds of those past students,” commented Chris.

the footings of the addition, with walls to follow. The goal of Phase 2 is for the front of the school to mimic the original front of the building. As you enter the school from the front and walk up the stairs, holding the gorgeous wood railing that so many students have done so before, and step into the main hall, it will look exactly like it did in 1916 with classrooms to the left and right. You will not see the large addition behind the school to the east. “We cannot wait to hear the memories that will flood the minds of those past students,” commented Chris.